Round Rock TX Roof Evaluations

Determining if a roof is a candidate for restoration begins with an evaluation of its current condition. But a standard visual inspection won’t cut it.

Gone are the one-size-fits-all checklists and the subjective opinions that differ greatly based upon a roof technician’s level of experience – both of which are common elements of inspections within the commercial roofing industry.

BesTex’s technology-based BesTex evaluations dig deeper. Data, photos and a core sample are collected from the roof and sent to our state-of-the-art laboratory for extensive testing and analysis. The end result is a report that supplies facility managers with all of the knowledge needed to make informed decisions about their roof. No guesswork required. No opinions accepted.

LET’S WALK THROUGH A BESTEX EVALUATION

Step 1: Visual Analysis

- Trained technicians inspect the entire roof for problem areas or anomalies. If defects are discovered, they input the type, size and quantity found into a tablet that’s loaded with BesTex software. This proprietary software dictates the data collection criteria by roof type since anomalies possible on a single-ply roof system, for example, can differ greatly from those possible on a metal roof. Furthermore, there is required data collection for the roof surface and its structural components – both interior and exterior – complete with descriptions and photos. The data is viewed by experienced BesTex specialists in a Work In Progress (WIP) room at the same time as its being recorded on the tablet, all of which is designed to prevent subjectivity and assure accuracy of the data.

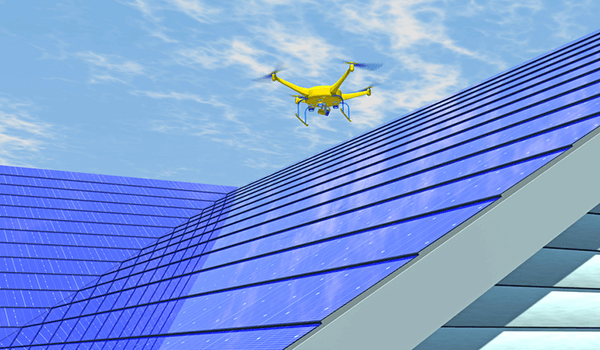

Step 2: Thermal (Infrared) Scan

- The only way to effectively determine the presence of wet insulation is through an infrared scan. It’s a critical step in the inspection process because when left untreated, wet insulation can lead to energy loss (and higher utility costs), mold and bacteria growth, insect and pest contamination, structural damage and more.

Step 3: Laboratory Analysis

- In addition to the vast amount of data collected, we take a core sample from each roof and send it to a, ISO 9001:2015 -certified lab. There, it goes through extensive structural and chemical testing, including IR analysis, to test elongation, tensile strength and other key indicators of roof life expectancy.

Step 4: Data Analysis

- Once the visual analysis is completed, the data collected is automatically sent to our Simetrix database, which houses all of the data collected through years of roof evaluations. It is constantly being fed new data, making it continuously smarter. This data, combined with the results of the laboratory testing, result in a condition report of the roof that includes an objective and accurate prediction of remaining useful life based upon the three testing methods: visual inspection/data collection on the tablet, infrared scan and core sample analysis.

Through this exhaustive scientific analysis, the BesTex team is well equipped to determine the most cost-effective solutions to extend the roof life.

Our Round Rock Roof Repair Guarantee

Our Round Rock Roofing Awards